Amprius Supercharges U.S. Battery Production Just as Drones Take Off

Amprius Technologies is revolutionizing drone batteries with high-energy silicon-anode cells, promising longer flights and powering the future of UAVs.

It’s official: the skies are buzzing with more drones than ever, and one California company is making sure those buzzing machines don’t run out of juice mid-air. I'm talking about Amprius Technologies, a Silicon Valley battery maker with roots in Stanford research labs, has just increased its production of its futuristic silicon-anode batteries in Fremont. ). And the timing couldn’t be better—the global drone market is exploding, with analysts projecting battery demand alone to hit nearly $50 billion by 2035—and everybody wants more flight time.

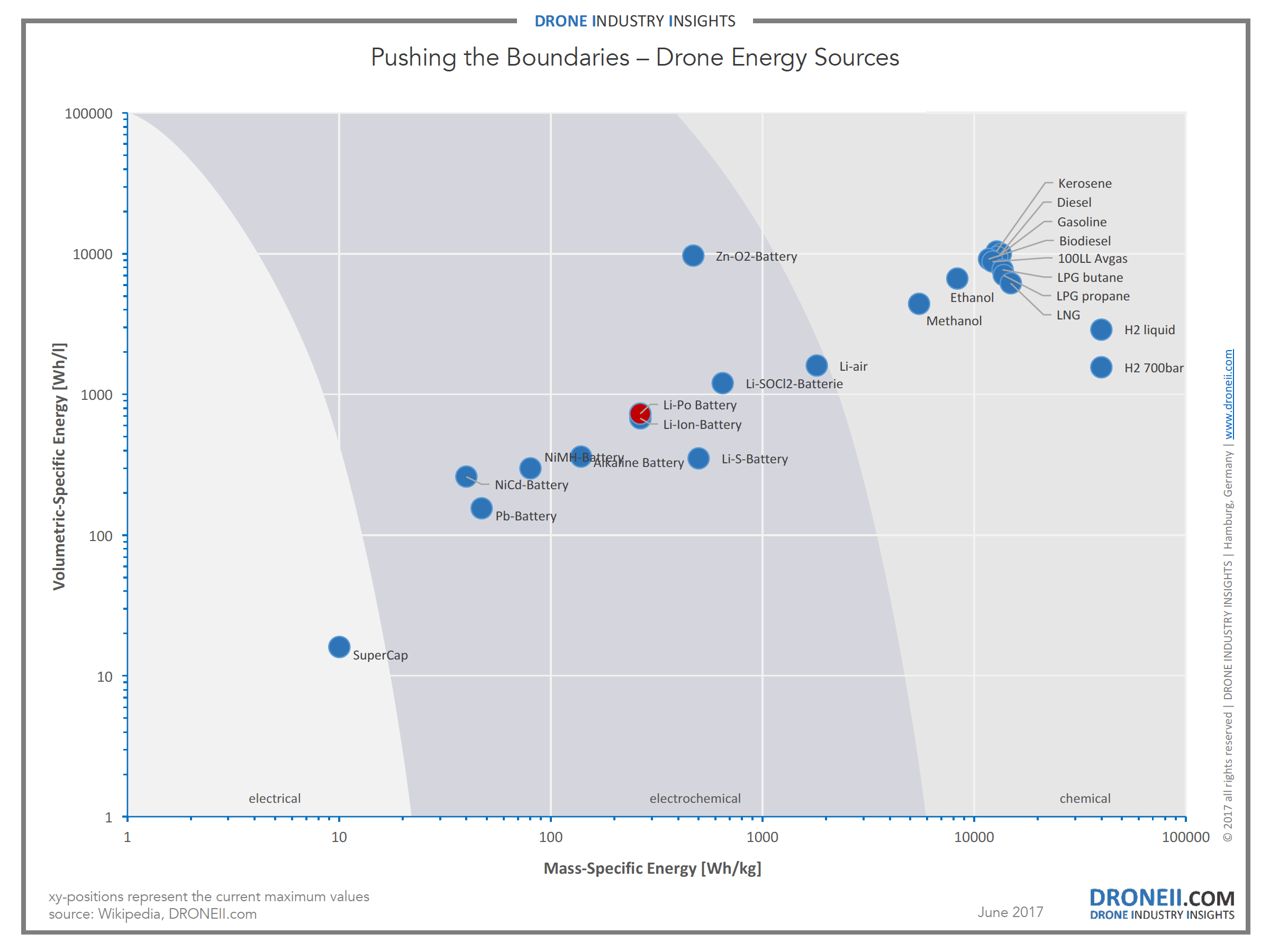

Batteries: The Secret Sauce of Flight

Let’s be honest—when you think about drones, you probably imagine spinning propellers, sleek carbon fiber bodies, or maybe Amazon packages dropping into your backyard. But none of that matters if the battery fizzles out after 20 minutes. Endurance is everything.

That’s where Amprius steps in. Its new SiCore cells pack up to 450 watt-hours per kilogram. If it all seems too complex for you, It just simply means that they store way more energy without adding extra weight. For comparison, the lithium batteries in most drones hover around 260 Wh/kg. That’s like swapping a bicycle for a high-speed train.

This tech isn’t just for your hobbyist quadcopter either. Think of high-altitude, long-endurance UAVs—the kind Airbus subsidiary AALTO flies to the stratosphere for surveillance and communication. With Amprius batteries onboard, those solar-powered aircraft can literally stay aloft for months. Imagine a plane camping above the clouds for an entire season. Wild, right?

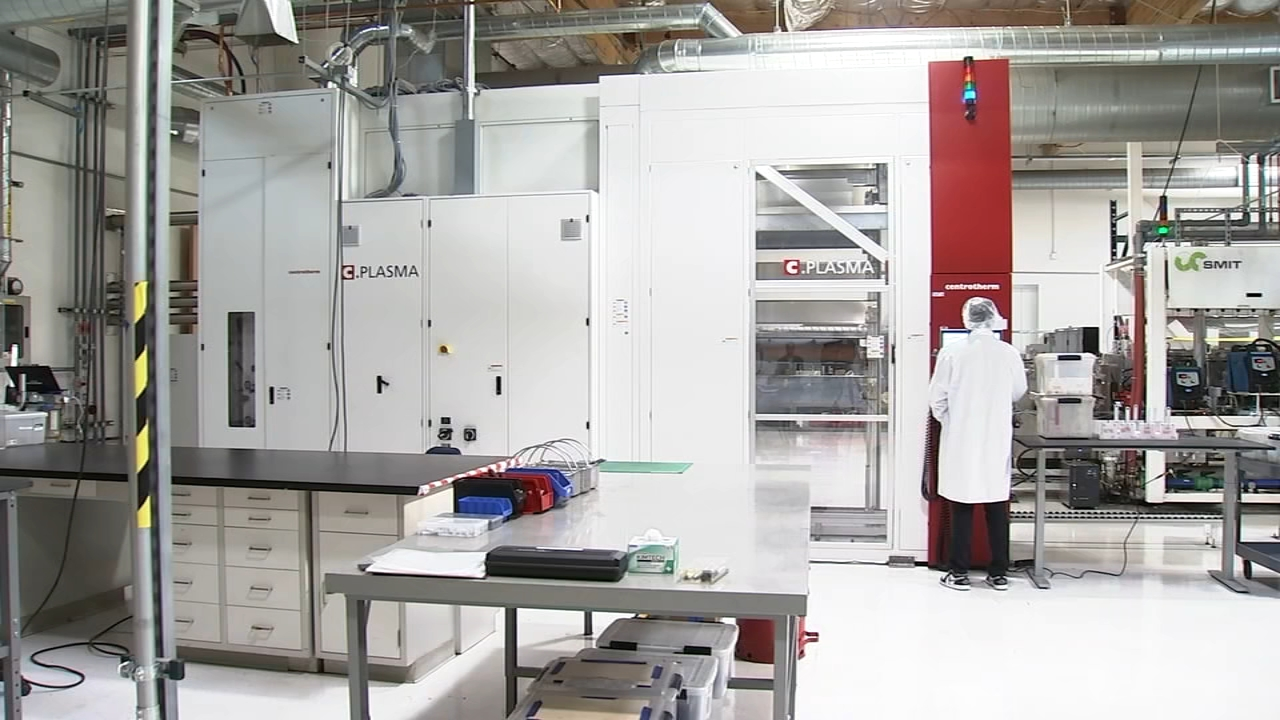

From Lab Bench to the Skies

Amprius isn’t some newcomer with big promises. Its scientists have been tinkering with silicon anodes for years, trying to squeeze every drop of energy into smaller, lighter packages. Now, the Fremont facility is moving beyond lab prototypes and are churning out production-ready SiCore cells for real-world customers.

That means companies like Airbus and other top-tier drone makers are getting real batteries, plugging them in, and flying them. CEO Dr. Kang Sun says demand is so strong they had to expand production just to keep up. And here’s the kicker: the cells aren’t one-size-fits-all. Some are tuned for maximum energy (perfect for long endurance missions), while others balance energy and power (for quicker, more agile maneuvers).

Scaling Without Going Broke

Of course, building a giant battery factory costs a fortune—just ask Tesla. Amprius is taking a smarter, lighter approach. The Fremont site handles pilot production and early customer deliveries, while large-scale manufacturing is handled through contract partners overseas, including a big deal in South Korea. In total, Amprius now has over 1.8 gigawatt-hours of manufacturing capacity lined up.

That’s a fancy way of saying: “We can scale like crazy without pouring billions into concrete.”

The Drone Market Is on Fire

If you’re wondering why all this matters, just take a look at the drone market forecast. Analysts expect the drone battery sector alone to balloon from around $9.5 billion in 2025 to nearly $50 billion by 2035. That’s not growth—it’s liftoff.

The reason? Drones are everywhere. Militaries use them for reconnaissance. Farmers use them to scan crops. Inspectors use them for bridges and power lines. Logistics companies are testing package delivery. Emergency responders are sending them into places humans can’t easily go. And all of them want one thing: longer flight times.

That explains why Amprius is suddenly such a hot commodity. Its cells are not just “a little better”—they’re game-changing. And partnerships are piling up. One notable deal is with KULR Technology, which is building modular battery systems for drones using Amprius cells. The first systems—called KULR ONE Air—ship later this year, blending KULR’s thermal safety tech with Amprius’ energy-dense cells. Think of it as a Formula 1 pit crew teaming up with an engine builder: fast, efficient, and designed to win.

Investors Are Perking Up

Naturally, Wall Street is taking notice. Amprius’ stock price has seen a bump lately, thanks to these shipments and performance milestones. Some analysts are betting big, calling the company’s silicon-anode tech a potential “category disruptor.” And with the Fremont pilot line proving it can deliver, the hype is starting to match reality.

The Bottom Line

Drones are no longer toys—they’re turning into workhorses of the modern world. And like every workhorse, they need fuel. Amprius isn’t just making batteries; it’s making the difference between a 30-minute flight and a 30-hour mission.

By shipping real, production-ready cells from U.S. soil while scaling globally through partners, the company is threading the needle between innovation and scalability. And if the drone industry grows as fast as predicted, Amprius is positioning itself as the battery brand every drone maker wants inside their flying machines.

So, next time you look up and see a drone buzzing overhead—whether it’s filming a concert, scanning farmland, or cruising above the stratosphere—there’s a good chance it might be powered by a little slice of silicon wizardry from Fremont.

If you’re as curious as we are about where this tech is headed next, keep your seatbelt fastened and stay tuned to our blog for more.

Comments ()